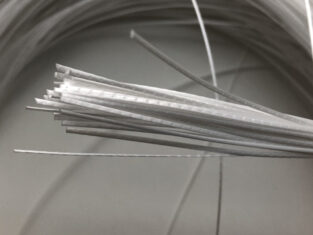

For what reason that the finished embryonic filament, rolled fabric, rolled belts( loops ) can be used as raw materials for FIBC big bag manufacturers. The finished embryonic filament is one of the important links in the whole process. The finished embryonic filament is based on the final tape winder at the filament extrusion plant, the finished embryonic yarn will be placed on the warp yarn creel for the circular loom and needle loom links to complete with fabric weaving machine and belt weaving machine. Therefore, in the extrusion line and tape winder part, the quality of the tape winder will also affect the use of embryonic filament in the next process.

Different Tape Winder Machines

Magnetic Dynamical Control Tape

High-Speed Frequency Coversion Tape Winder

Double-Working Unit Tape Winder

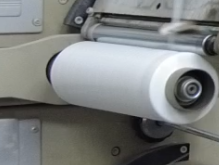

For FIBC big bag manufacturers with self-production ability, different tape winder machines will have different choices. Formerly, at the filament extrusion process, it mostly involved the design of magnetic dynamical control tape winder, deviation transmission and only mechanical structure, but it occupied the large area. As the manufacturing enterprise, it is necessary to consider the space of the whole plant and the ratio of personnel. Besides, there are high-speed frequency conversion tape winder, cast panel and shell, which occupy small area and are relatively suitable for plants with limited space and low ratio of personnel.

Moreover, there is double-working unit tape winder. Compared with the both them, it solves the labor cost relatively higher, so that can realize automatic changing rewinding. For the workshop tansformation and upgrading to intelligent, large and medium-scale company factories, it can be put into use relatively.