Big Bag Spout Sewing Machine

Model

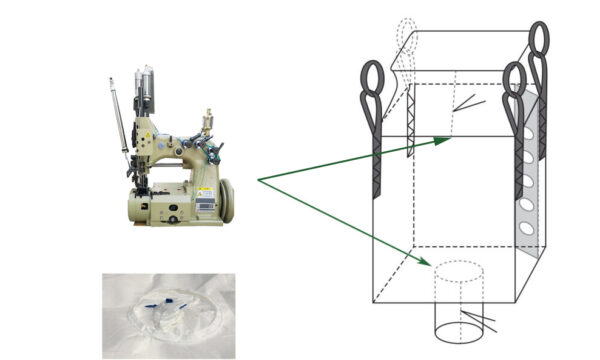

80700CD4HLSQL

Our Big Bag Double Needle Chain Stitch Sewing Machine is mainly used to sew various pieces of container bag body, mainly including,

- container bag side seam on fabric and loop with filler cord,

- bulk bag top and bottom panel seam with filler cord,

- jumbo bag very heavy duty corner seam etc.

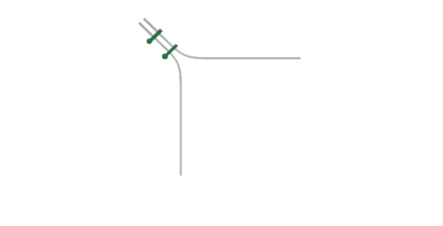

The 2 needle, 4 thread chain stitch(401+401) sewing machine with two parallel double row stitch.

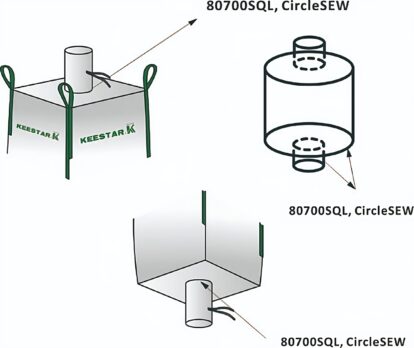

The FIBC Sewing Machine is equipped with a specially designed cylindrical working table to facilitate circular seam of jumbo bag top and bottom panel with spout fabric.

The sewing capacity can reach a thickness of Max. 18 mm, which meets the sewing process requirements of all jumbo bags.

Models

▪ Manual Presser Foot Lifter, basic Model 80700CDSQL

▪ Pneumatic Presser Foot Lifter, Model 80700CD4SQL

▪ Pneumatic Presser Foot Lifter+Needle Cooling+Left Side Pneumatic

Operated Hot Cutter, Model 80700CD4HLSQL

Details

Model 80700CD4HLSQL is latest design cylinder bed 2 needle, 4 thread chain stitch(401+401 parrallel) sewing machine with two parallel double thread chain stitch. Cylinder bed could insert into filling and discharging spout tube, helps easily operate a 360° circle stitch to attache to the bags.

Equipped with both plain and alternating upper fabric feeding system it’s also suitable for inserting top and bottom plate and body side seams on very heavy weight fabric of container bags, and with top and bottom filler cord guides for sealing the needle punctures.

Features of Big Bag Container Spout Sewing Machine

◥ Adjustable Stitch Range 6 to 12 mm, Standard 10 mm

◥ Extra Heavy Duty 18 mm Sewing Capacity

◥ Tube Attache Seam, Side seam, Top and Bottom Plate Seams

Model | 80700CD4HLSQL |

|---|---|

Stitching Type

| 401+401 |

Needle Distance

| 7.2mm |

Sewing Capacity

| up to 18mm |

Standard Needle

| 9848GA 300# |

Stitch Range

| 6 to 12mm (Standard Setting 10mm) |

Speed

| up to 1,400rpm |

R2U Delivery Service

Considering the actual demand of container bags manufacturer, we start to provide a READY TO USE delivery (R2U Delivery) service.

With a R2U delivery service, we will provide:

Model 80700CD4HLSQL– Big Bag Spout Sewing Machine

Enclosed Automatic Lubrication

Servo Motor Drive

Spout Style Bench Top and Stand

Multi-function Control Pedal