FIBC Big Bag PE Liner Making Machine

Model

LinerSHAPE-B / L

Heat seal at the neck of the bottle, heat seal at the bottom of the cross-section, heat seal on both sides of the cross-section.

Liner Type:

▪ Top and Bottom Bottle Neck Liner.

▪ Top Bottle Neck Liner.

▪ Flat Bottom Liner.

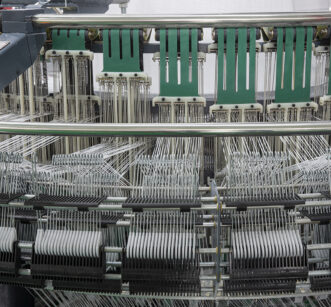

◥ Welding the PE In-liner from Tubular Film

◥ Automatic Film Feeding

◥ Double Side Straight Welding

◥ Bottle Neck Sealing

◥ Automatic Cold Cutting to Length

◥ Manual Edge Film Trimming

◥ Edge Control Device

◥ Deviation Correction Device

Model

LinerSHAPE-U

Heat seal at the neck of the bottle, heat seal U shape and holing U cut, heat seal at the bottom of the cross-section.

Liner Type:

▪ U Liner

▪ Flat Bottom Liner

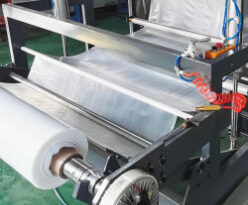

◥ Welding The PE In-liner from Tubular Film

◥ Automatic Film Feeding

◥ Double Side Straight Welding

◥ Bottle Neck Sealing

◥ Automatic Cold Cutting to Length

◥ Manual Edge Film Trimming

◥ Edge Control Device

◥ Automatic U Shape Edge Trimming with Hot Punching

◥ Deviation Correction Device

Model Different Table

Model | LinerSHAPE-B/ L |

|---|---|

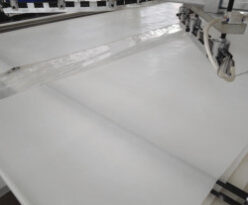

Film Type | Tubular Film (gusseted) |

Width | Max. 1,200mm |

Max. Film Roll Dia. | 1,000mm |

Film Thickness | 0.08-0.12mm |

Welding Width | 8mm |

Finished Bag Length | 1,500-5,000mm |

Length Accuracy | ±2mm |

Output | 60-100pcs/h |

Heating Power | 10kW |

Model | LinerSHAPE-U |

|---|---|

Liner Length | 1,000-4,000mm |

Heat Sealing Width | 8mm |

Feeding Accuracy | ±2mm/mtr |

Output | 60-180pcs/h |

Max. Material Roll Dia. | φ1,000mm |

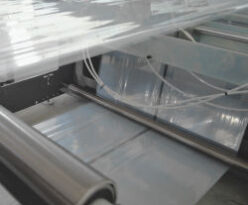

Automatic Deviation Rectifying | ±150mm |

U Shape Size | Customized, 8mm Heating Width |

Straight Heating Knife | 2,200mm Length, 8mm Heating Width |

Heating Power | 9kW |

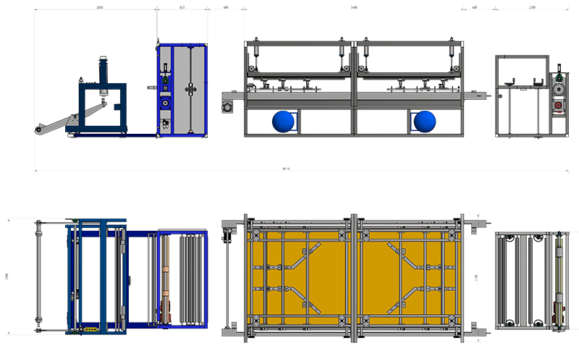

LinerSHAPE-B / L

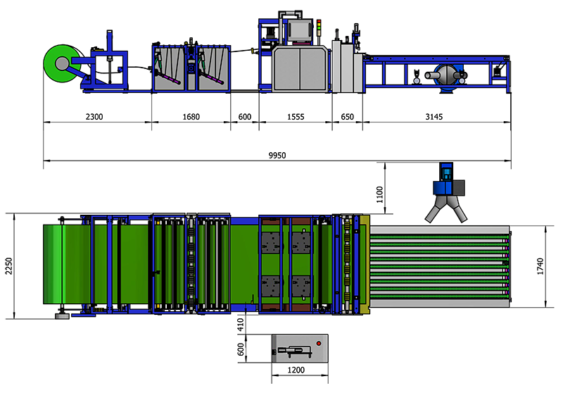

LinerSHAPE-U

Model LinerSHAPE – FIBC Big Bag PE Liner Making Machine

Simple and Easy to Control

Easy Maintenance

Strong Stability

Energy Efficiency Design