Model

Strapex

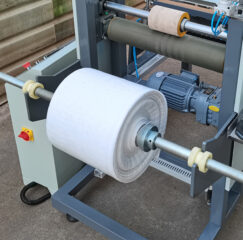

Our Handle Wrapping Sewing Unit for 1-2 Loops Big Bag has a built-in automatic program, which can tighten, cut and sew 1-2 loops of the container bag with just one button operation, effectively solving the problem of uneven tightness of wrapping fabrics caused by manual operation.

The Handle Wrapping Sewing Unit for 1-2 Loops Big Bag adapts to the development needs of industrial automated packaging.

Through automated operation, it greatly improves the production efficiency and product consistency in the process of 1/2 loops for jumbo bags, making it easier for enterprises and factories to organize production efficiently and achieve product standardization.

Model STRAPEX is an automatic, compact, easy operating, labour saving machine for handle wrapping making for 1/2 loops FIBC big bags. Sewing and handle wrapping fabric trimming will be automatically process.

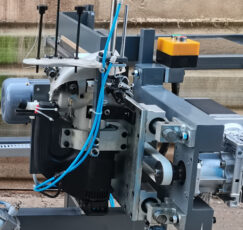

● Solve the problem of not handle wrapping fabric tightening and poor unity.

● Built-in circular fabric cutting device, to make wrapping the fabric incision neatly.

Features of Big Bag Handle Wrapping Sewing Machine

Specification of 1 or 2 loops Big Bag Handle Wrapping Sewing