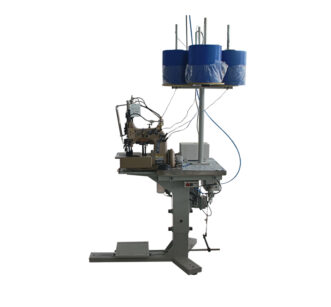

High Speed Big Bag Lockstitch Sewing Machine

Model

1510

Our Big Bag Lockstitch Sewing Machine is mainly used to sew various pieces of FIBC container bag(when chain stitching sewing is not required), mainly including,

- container bag loop seam on fabric ,

- container bag spout fabric seam,

- big bag side seam on fabric,

- bulk bag top and bottom panel seam,

- jumbo bag very heavy duty corner seam etc.

The High Speed Heavy Duty Lockstitch Sewing Machine adopts upper and lower feeding and needle feeding, which is suitable for sewing thick materials and multi-layer materials.

- The working space is larger, 360×100 mm.

- The sewing speed is higher, up to 2500 rpm.

▪ Needle type: DPx17

▪ Presser foot lift: 16 mm

▪ Triple feed

Model 1510 is a general model for manual loop sewing on jumbo bag body in FIBC industry worldwide.

Types:

▪ Model 1510L14-7, with auto presser foot lifter, thread trimming,

back tack

▪ Model 1510L14DT same with 1510L14-7 and with servo motor direct

driven

Model 1510L25-DT

Details

Keestar offers corresponding driving forms on basic model 1510 to meet diversified sewing operating demands from customers.

With servo motor direct driving, triple operating pedal with three separate pedals separately drive the sewing machine to run with forward sewing, reverse sewing, pneumatic presser foot lifting, sewing operators could operate the sewing machine while standing, model 1510.

With servo motor driving, pneumatic presser foot lifting, pneumatic reverse sewing, needle position, automatic upper and lower thread trimming, multi-function control pedal, model 1510-7.

With servo motor direct driving, maximal driving power transmission, covers all functions of model 1510-7, model 1510DT.

14″, 18″ and even larger working space version customized.

Model 1510 – High Speed Big Bag Lockstitch Sewing Machine

Servo Motor Driven ( Model 1510DT )

Larger Working Space ( Model 1510L25-DT )

Strong Stability

Easy to Operate