Tape Stretching Line

Model

TEX

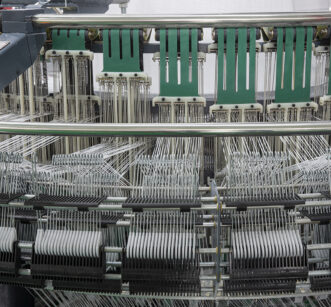

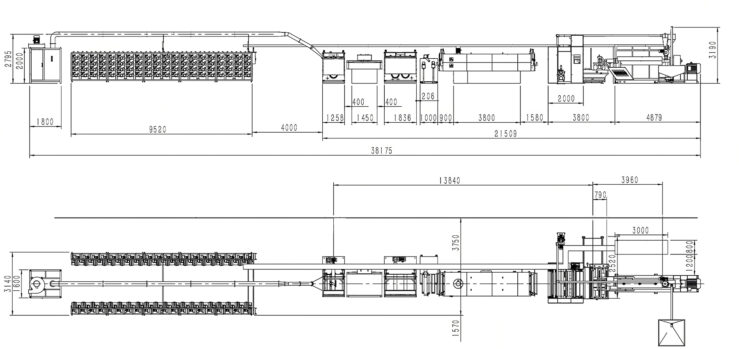

Tape Stretching Line is composed of multiple pieces of equipment, and the complete set of equipment is versatile.

The production process includes multiple processes, namely heating (polypropylene resin), extrusion, cooling, blank cutting, stretching, shaping, winding, etc.

According to the diameter of the extruder screw (material rod), our Tape Stretching Lines are available under three machine models: TEX-90, TEX-105 and TEX-120.

The Tape Extrusion Line reflect the design features: professionalism, adaptability, high output, low consumables, and cost-effectiveness.

Features of Tape Extrusion Line

Model | TEX-90 | TEX-105 | TEX-120 |

|---|---|---|---|

Extruder | 90 | 105 | 120 |

Maximum Melt Capacity – PP | 330kg/hr | 450kg/hr | 600kg/hr |

Working Wide | 1,000mm | 1,200mm | 1,500mm |

Process Line Speed

| 350 mtr/min | 350 mtr/min | 350 mtr/min |

Air Supply | 0.6-0.8Mpa | 0.6-0.8Mpa | 0.6-0.8Mpa |

Power Supply | 380V, 3 Phase with L3 AC+TN-C-SN ,E-50Hz | 380V, 3 Phase with L3 AC+TN-C-SN, E-50Hz | 380V, 3 Phase with L3 AC+TN-C-SN, E-50Hz |

Option List – Tape Extrusion Line

Model TEX – Tape Stretching Line

Special Design for Big Bag Fabric Tape

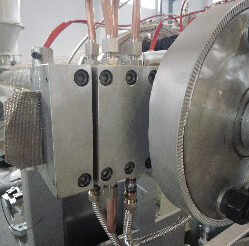

Dual T-die Available

Strong Stability

Energy Efficiency Design